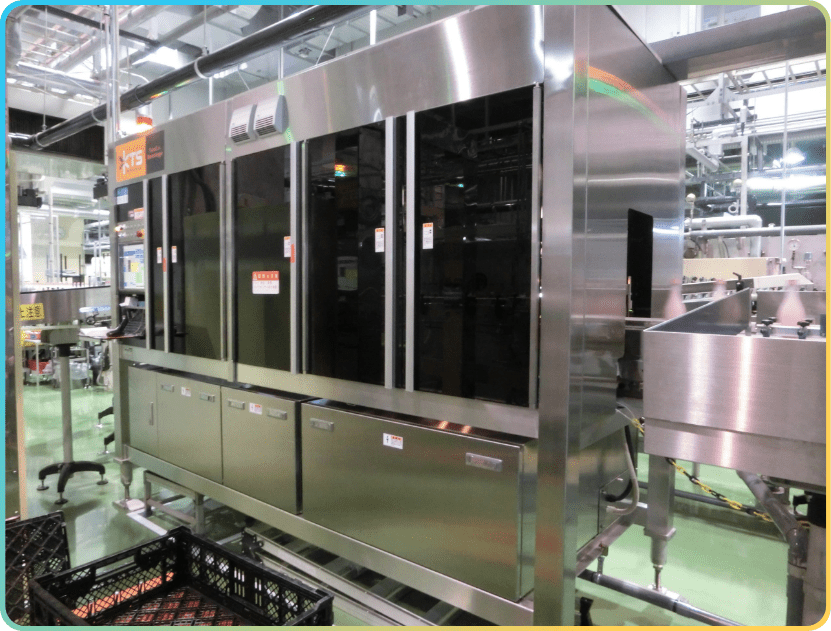

Our Comprehensive Bottle Inspection Services

Our Comprehensive Inspection Services guarantee a complete QC of your product. From the empty container to the final packaged case. We utilize advanced AI vision to perform both Empty Bottle Inspection (EBI) and Full Product Inspection across your entire line.

We ensure every product is flaw-free, checking for cosmetic defects, foreign materials, correct labeling, and accurate traceability codes before it reaches the consumer. Zero-defect production starts here.

Detect Floating Foreign Material

Our specialized lighting and high-speed cameras are tuned to detect floating foreign material (floaters) or particulates suspended within the liquid product. This ensures unmatched product purity and eliminates costly recalls associated with internal contamination.

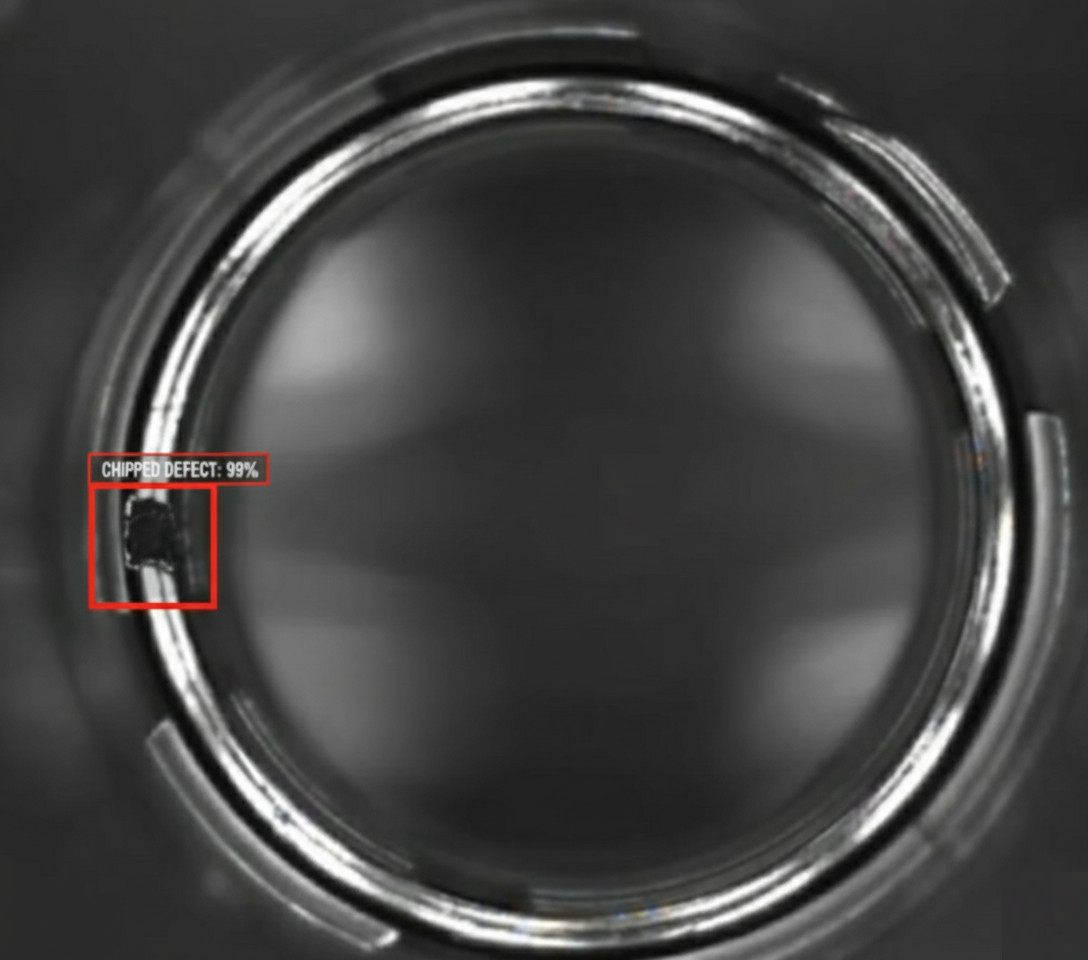

Glass Rim Integrity: No More Chipped Glass Rims

Even the smallest chipped glass rim can compromise safety and lead to product spoilage. Our EBI systems use precision optics to scan the entire rim surface (chip-to-rim detection), automatically rejecting any bottle with damage, guaranteeing a perfect seal.

Final Packaging Check: Case Partition Verification

We extend our inspection to the final packaging stage. Our vision systems verify the presence and correct positioning of case partitions to ensure maximum protection during shipping, preventing bottle-to-bottle contact damage and structural failure of the case.

Labeling & Traceability Excellence

Maintaining brand consistency and meeting regulatory requirements means perfect labels and codes. Our systems verify every detail.

Correct Label Presence & Position

We verify the presence, type, and angular positioning of all labels (front, back, neck). This ensures every product meets aesthetic standards and regulatory requirements for label content and placement.

Damaged Label & Scuff Detection

Using high-contrast imaging, our AI models identify aesthetic flaws like tears, creases, ink smears, or damage on labels. This quality check ensures your brand image remains impeccable and prevents consumer complaints about substandard presentation.

Correct Lot & Date Code Verification

Through Optical Character Verification (OCV), we check for the correct lot and date codes. This includes verifying print quality, legibility, and accuracy against the batch requirement, ensuring complete traceability and compliance.

Why Implement Full Product Inspection?

Implementing Full Product Inspection (FPI) moves your quality control from reactive to proactive. It guarantees consumer safety by eliminating foreign material and glass defects, while simultaneously protecting your brand's value through perfect aesthetics and compliance with all traceability requirements.

Flexible Vision's Safety and Compliance Advantage

Our comprehensive inspection suite is engineered to simplify complex regulatory landscapes. By verifying every detail—from the structural integrity of the container to the accuracy of the date code—we provide an unshakeable audit trail and compliance foundation.

Ready for Flexible

Vision's Full-Spectrum Inspection?

Elevate your manufacturing with our advanced vision services. It's time that your products consistently meet the highest standards of quality, safety, and compliance.

Get in touch now

Frequently  Asked Questions

Asked Questions

Our system performs checks for chipped glass rims, floating foreign material inside the product, verifies correct labels and detects damage on labels, checks correct lot and date codes, and confirms case partition integrity.

We use high-precision Optical Character Verification (OCV) to ensure the code is present, legible, accurate, and matches the correct format and batch information for full traceability.

Yes, our vision systems are designed for flexibility and can be adapted to inspect a wide variety of materials, sizes, and shapes, including both glass and various plastic containers.

Inspecting case partitions ensures the protective dividers are present and properly aligned, preventing product damage during transport and safeguarding the integrity of the final packaged goods.

Absolutely. Our machine vision systems are highly configurable. We can fine-tune the detection sensitivity, tolerance ranges for label placement, and code formats to match your exact product specifications and quality standards.