How Machine Vision Is Replacing Quality Control Teams

Apr 24th. 15 minutes read

Quality control is a crucial component of modern manufacturing, ensuring products meet industry standards before reaching consumers. Traditionally, human inspectors played an essential role in this process, manually inspecting products for defects and inconsistencies. While this method has been effective, it is prone to human error, fatigue, and inefficiencies, particularly in high-speed production environments.

However, with the rise of automation and artificial intelligence, machine vision cameras are increasingly replacing quality control teams. These advanced imaging systems enhance precision, reduce errors, and significantly improve efficiency across industries. By leveraging high-resolution imaging, AI-powered analysis, and real-time data processing, machine vision technology ensures that products meet stringent quality standards with unmatched accuracy.

This article explores how machine vision technology is revolutionizing quality control, its benefits, and why manufacturers are rapidly adopting it to optimize production processes and remain competitive in an evolving market.

What Is Machine Vision?

Machine vision is a technology that enables computers to interpret and analyze visual information from the physical world. By using advanced machine vision cameras, sophisticated algorithms, and deep learning techniques, these systems can inspect products with remarkable accuracy.

Components of Machine Vision Systems

A typical machine vision system includes:

- Industrial Cameras: Capture high-resolution images of products.

- Lenses: Enhance image clarity and focus on fine details.

- Lighting Solutions: Improve image contrast for better defect detection.

- Processing Units: Use AI and machine learning algorithms to analyze images.

- Software Interfaces: Provide real-time insights and quality assessments.

The Limitations of Traditional Quality Control Teams

While human quality control inspectors have been the standard for decades, they have several limitations:

- Human Error: Even skilled inspectors can overlook defects, especially in high-speed production lines.

- Fatigue and Inconsistency: Human efficiency declines over time, leading to inconsistent results.

- Slow Processing Time: Manual inspections take time, slowing down production.

- High Labor Costs: Hiring and training quality control staff can be expensive.

In contrast, machine vision cameras operate with unmatched speed, consistency, and accuracy, making them a superior alternative.

How Machine Vision Cameras Improve Quality Control

Machine vision technology has transformed quality control in several key ways:

1. Superior Accuracy and Defect Detection

Human inspectors can miss small or subtle defects, but machine vision systems are designed to detect even microscopic flaws. With high-resolution imaging and AI-powered analysis, machine vision cameras can identify inconsistencies in products with unparalleled precision. Advanced algorithms can detect scratches, misalignments, and missing components with incredible accuracy.

2. Speed and Efficiency in Manufacturing

Machine vision operates at lightning-fast speeds, inspecting thousands of products per minute without fatigue. This speed ensures manufacturers maintain high throughput while upholding strict quality standards. Automated inspections allow manufacturers to process orders faster and meet customer demands more efficiently.

3. Cost Savings and Return on Investment (ROI)

By reducing labor costs and minimizing defective products, machine vision systems provide a significant return on investment. Manufacturers can reallocate resources to other critical areas, improving overall productivity. Additionally, fewer recalls and product defects result in lower warranty claims and improved brand reputation.

4. Consistency and Reliability

Unlike human inspectors, machine vision systems work 24/7 without fluctuations in performance. Their consistency ensures every product undergoes the same rigorous inspection, eliminating variations caused by human subjectivity. This uniformity is essential for industries with strict compliance requirements.

5. Real-Time Data and Predictive Maintenance

Machine vision systems provide real-time data on production quality, enabling manufacturers to address defects immediately. Additionally, predictive maintenance capabilities help prevent equipment failures, further improving operational efficiency. With machine vision integrated into the Industrial Internet of Things (IIoT), manufacturers can track performance analytics and optimize workflow.

Industries Benefiting from Machine Vision Technology

Machine vision is revolutionizing multiple industries, including:

1. Automotive Industry

Automobile manufacturers use machine vision cameras to inspect components for defects, ensuring safety and compliance with regulatory standards. These systems analyze welding seams, measure component dimensions, and verify correct assembly placement. Additionally, machine vision aids in robotic guidance, helping automate vehicle assembly with higher precision.

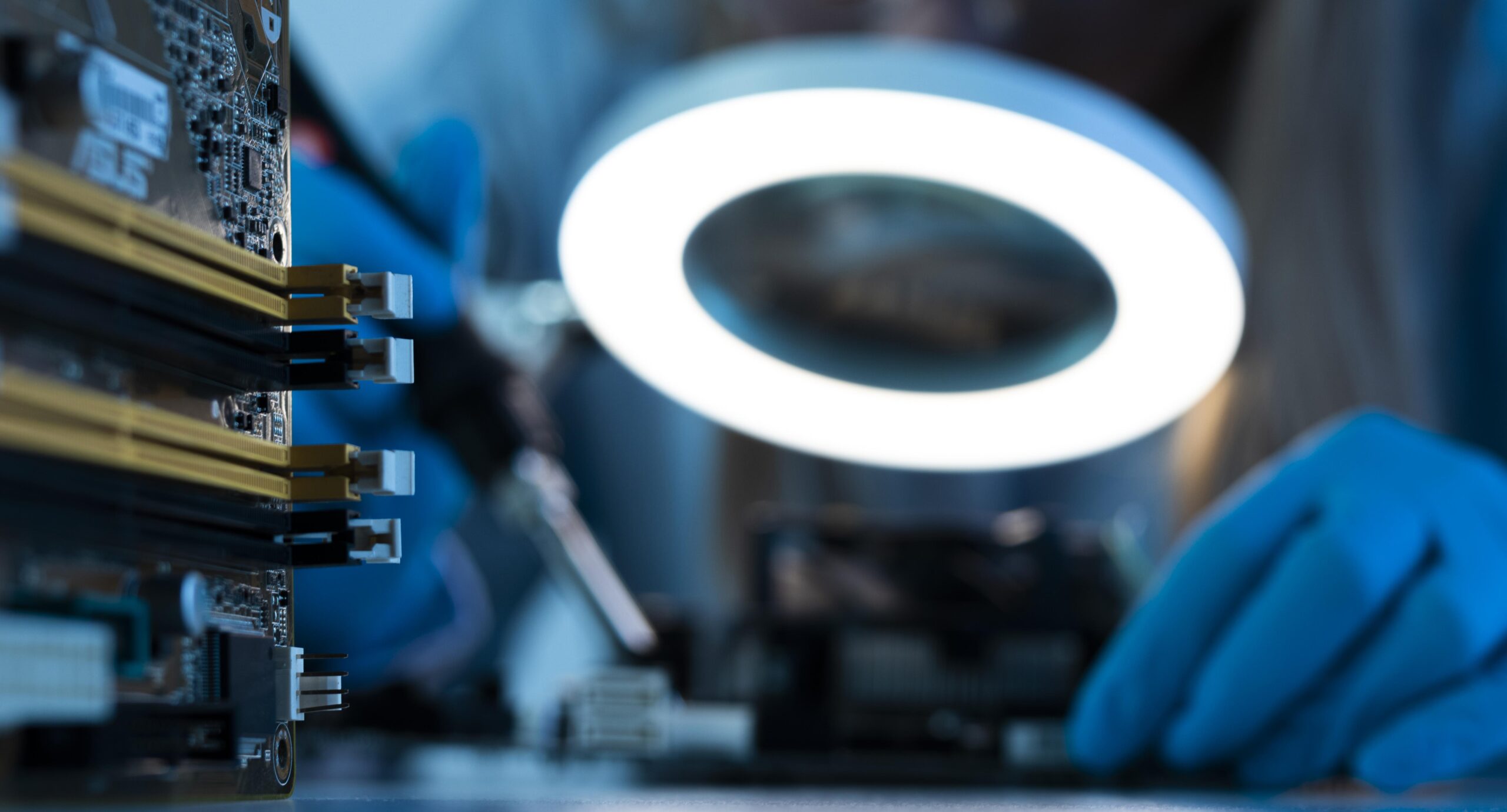

2. Electronics Manufacturing

From circuit boards to microchips, machine vision ensures precision in assembling electronic components, reducing failure rates. Automated visual inspections identify soldering defects, missing components, and misalignments with pinpoint accuracy. These systems also help detect performance inconsistencies in semiconductor manufacturing.

3. Food and Beverage Processing

Food manufacturers utilize machine vision for quality control, checking packaging, expiration dates, and contaminants. These systems ensure that labeling is accurate, seals are intact, and foreign particles are detected before distribution. Machine vision also helps classify products based on size, color, and texture, improving sorting efficiency.

4. Pharmaceutical and Medical Devices

Machine vision ensures pharmaceutical products meet strict safety standards by verifying labels, packaging, and pill integrity. Automated inspections help prevent costly recalls and ensure compliance with FDA and other regulatory bodies. Machine vision also plays a crucial role in medical imaging, assisting in diagnostics and surgery planning.

5. Aerospace and Defense

High-precision parts require flawless quality control, and machine vision plays a vital role in inspecting aircraft components and defense systems. The ability to detect hairline fractures, deformations, or inconsistencies ensures the reliability and safety of critical components. Machine vision also supports automated welding, assembly, and structural integrity testing in aerospace engineering.

The Future of Machine Vision in Quality Control

As artificial intelligence and deep learning continue to evolve, machine vision cameras will become even more advanced. Future advancements will include:

- Enhanced AI Algorithms: Improved deep learning models for better defect detection.

- 3D Vision Systems: Providing depth perception for complex inspections.

- Integration with Robotics: Combining machine vision with automated systems for seamless production lines.

- Cloud-Based Data Processing: Enabling remote monitoring and predictive analytics.

Conclusion: The Era of Machine Vision in Manufacturing

Machine vision technology is rapidly transforming quality control, providing businesses with unmatched accuracy, efficiency, and cost savings. By integrating machine vision cameras, manufacturers can eliminate human error, streamline production, and ensure superior product quality. These systems enhance operational workflow by automating inspections, reducing waste, and increasing throughput, leading to a more sustainable and profitable manufacturing process.

With continuous advancements in AI and imaging technology, machine vision is set to dominate the future of quality control. Cutting-edge developments in deep learning, 3D vision, and hyperspectral imaging are pushing the boundaries of defect detection and process optimization. These innovations allow manufacturers to catch defects earlier in the production cycle, reduce recalls, and maintain stringent compliance standards with ease.

Businesses that adopt this technology today will gain a competitive edge, improve operational efficiency, and enhance customer satisfaction. Additionally, integrating machine vision cameras with IoT and cloud-based analytics provides real-time insights, enabling predictive maintenance and data-driven decision-making.

As industries continue to evolve, machine vision will play an integral role in shaping the future of manufacturing and quality assurance. To explore cutting-edge machine vision cameras, visit Flexible Vision.