Time Machine captures video replays of any event, such as a defect being detected or a part count not meeting the specification. Users can define how many seconds before and after should be captured and save videos of any event to the cloud.

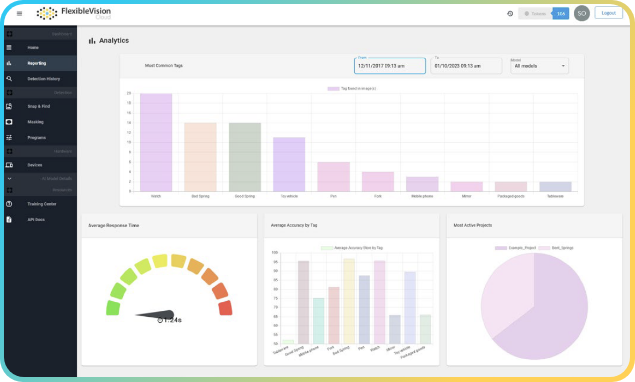

The analytics reporting page displays a variety of statistics for detected tags, accuracy and speed. Filters for projects and date ranges can be customized to display up to date information.

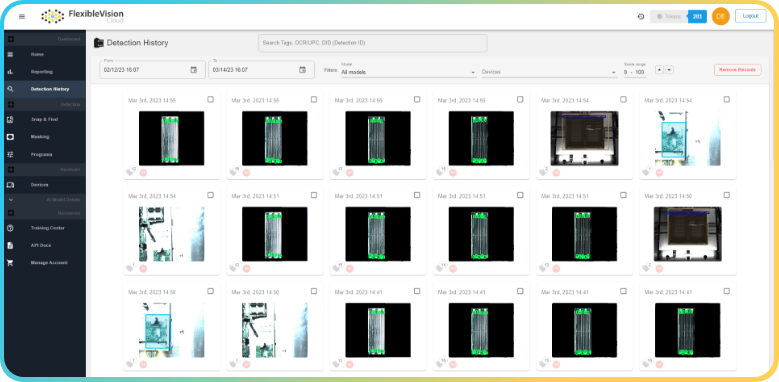

All images and detections are saved and can be found with custom filters or by searching for a specific tag, OCR, UPC, or detection ID.

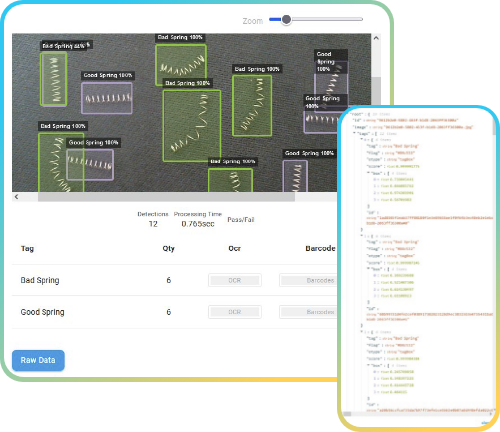

Detailed information on each tag detection can be found in the raw data that is stored with each image. This data can be used to drive further analytics and process improvement.

Observing each cog’s rhythmic dance, a symphony of precision unfolds on the production line’s stage. Data streams weave tales of efficiency, where every pulse is a note in the melody of progress.

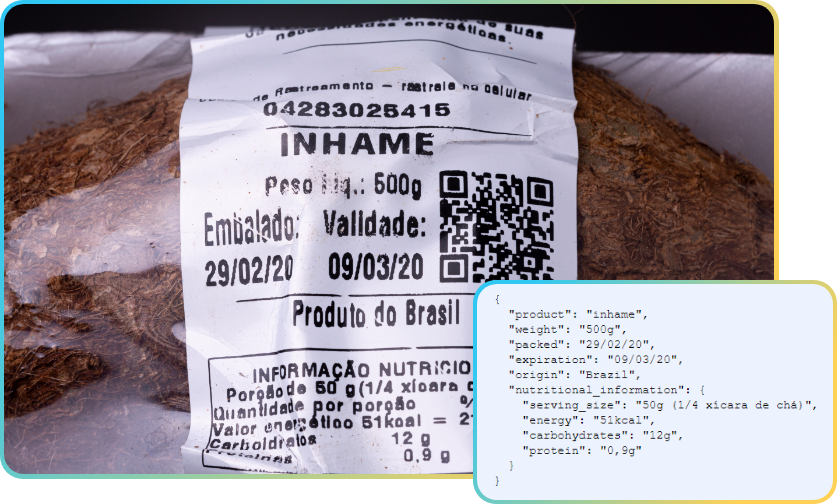

Unraveling labels, decoding symbols, packaging speaks volumes untold. In the fine print lies the narrative of consumption, revealing stories of origins and ingredients bold.

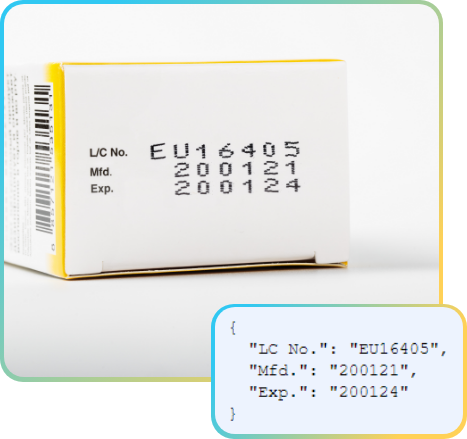

Ensuring authenticity with every scan, Lot Code Verification guards against counterfeit intrusion, securing trust in each product’s origin and quality.

Ensuring accuracy, labels undergo meticulous verification, safeguarding reliability in every application. Each label is a testament to precision, validated through rigorous scrutiny, instilling trust in its purpose.