Industry

IndustryAn end-to-end factory solution for all your machine vision needs

Flexible Vision enables your team to quickly solve difficult problems in an affordable, time-efficient manner.

Flexible Vision is an AI machine vision software and hardware application that works together to streamline visual inspections on the factory floor. We understand that all businesses need quality control, but traditional camera systems can’t solve the problem effectively.

Similarly, operators doing manual inspection is expensive and inefficient. After visual inspection, the cloud portal stores data so your teams can collaborate and share visual inspection programs across factory floors.

It’s never been easier to stay on top of your business’s needs.

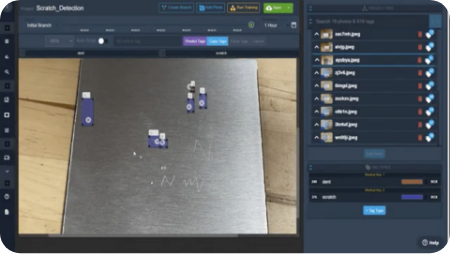

Our software seamlessly collects a series of 5-10 images, documenting both good and bad product inspections. The sample size can be optionally increased with augmentation, allowing your team to target issues and successes in one place.

Image tagging makes it simple to organize and locate your factory images. By using our cloud-based UI, you can tag images with the areas of interest.

This makes it efficient to share and collaborate on different image types.

A deep learning model will give you a comprehensive glimpse into your project, automatically storing it in the cloud for easy access. With the click of a button, your model will be created and ready for production in minutes.

After creation, your AI model will automatically deploy and prepare for validation. At this stage, you can download and sync your model to as many on-premise production lines as necessary. Our cloud-based software makes it simple to add production lines later on if needed.

Image storing is an advantageous feature that gives you a trackable and traceable timeline of your product. In case of error or recall, you can reference your cloud folder. All images will automatically sync to your cloud storage account. If you need to locate a file, you can search for images by date, time or serial number.

Our software allows for constant growth and progress as it evolves with your business needs. As your system collects more images, you may find new inspection criteria along the way. All of these images can automatically be included in your next model.

Speed is a necessity for streamlining the efficiency of your business. We prioritize your time with high-speed industrial processors that quickly process your images. All you have to do is select the AI model from the dropdown menu. Next, you can watch the detections arise live on screen.

Our systems are designed for manual inspection stations, or incorporation with traditional factory automation. All systems are IO and field-bus compatible. We make it simple to get your products to market free of defects or delays.

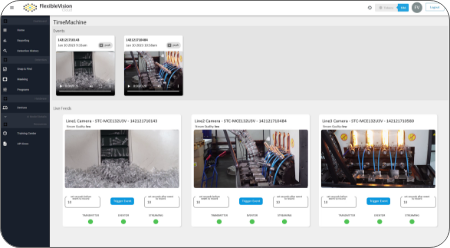

Data collection is an important aspect of product inspection, allowing you to archive images, look up factory videos, and trace issues on the factory floor.

Our AI-based cloud software makes it simple to search images based on your unique criteria details. You can endlessly store images to catch patterns and defects, all while building success strategies for future development.

By using our cloud-based tagging app, you can tag your image set quickly and easily. Our intuitive user interface is filled with shortcuts that reduce tagging time. All you have to do is add images to your dataset, tag, and train. It’s that easy.

Creating systems that are easy to use and effective for our customers is a top priority. That’s why you don’t need programming or technical experience to use our interface.

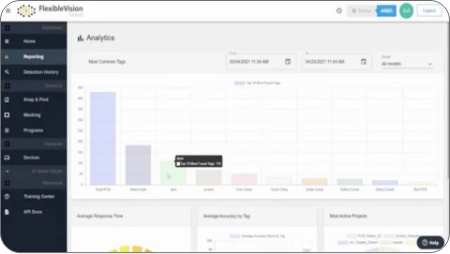

Your analytics dashboard will be the hub for all of your comprehensive analytics, highlighting detections across your factory floor. You can easily measure throughput and trend defect failures over time.

Our edge processors routinely sync their images and metadata, allowing you to view real-time dashboard updates. This advancement allows you to alert supervisors on the spot if irregularities are detected on the ground.

We offer AI machine vision systems that revolutionize visual inspections on the factory floor. Our technology combines software and hardware applications, delivering accurate results that traditional camera systems simply can't match.

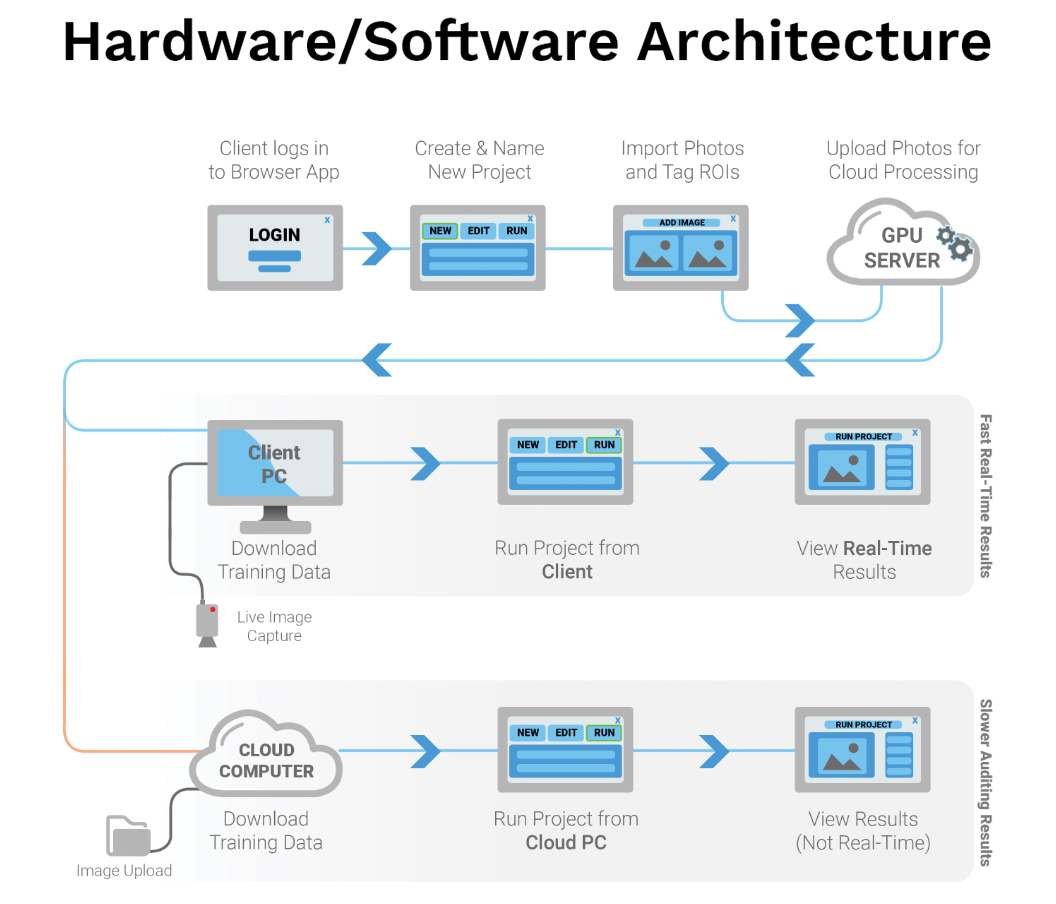

With our AI vision systems, you gain valuable insights into the inner workings of your production line. Below, we delve into the technology behind our systems and explore how they operate with precision.

Step by step, Flexible Vision's AI vision systems provide you with actionable insights and invaluable data. Our process ensures efficient data acquisition, preprocessing, advanced analytics, and insightful visualizations.

Data acquisition is the first crucial step in our technology. Our software collects a series of 5-10 images, capturing both good and bad product inspections. If needed, the sample size can be expanded with augmentation, allowing your team to focus on specific issues and successes, all in one location.

Organizing and locating your factory images becomes a breeze with our intuitive image tagging feature. Using our cloud-based user interface, you can easily tag images with areas of interest, making it effortless to collaborate on different image types across your teams.

But we don't stop there. We take your project to a comprehensive level through deep learning models. By employing powerful algorithms, we give you a detailed glimpse into your production line, automatically storing the results in the cloud for easy access. With just a click, your model is created and ready for production within minutes.

Once your AI model is created, it seamlessly deploys and prepares for validation. You can download and sync your model to as many on-premise production lines as necessary. And should your business grow and require additional production lines, expanding is simple and hassle-free.

Here’s everything you need to know about our hardware solutions.

We understand the importance of convenient machine vision integration and implementation. Our AI vision systems integrate into your current infrastructure, ensuring a smooth process that maximizes the benefits of AI technology.

Whether you have an existing setup or are starting from scratch, our team of experts will guide you every step of the way. We work closely with you to understand your unique needs and customize the implementation process accordingly.

Partner with Flexible Vision today and unlock the true potential of AI machine vision systems.