Inspection Systems

Inspection SystemsWelcome to Flexible Vision. Our passion is your success. We design our Fill Level Inspection Systems with one goal in mind: to enhance your production processes with quality and efficiency.

Every product you create will meet, and even surpass, the highest standards of consistency, quality control, and regulatory compliance. Expect nothing less than perfection for your customers

Inspection Systems?

Inspection Systems?Say goodbye to underfilling and overfilling, and hello to product consistency and quality control. Our Fill Level Inspection Systems not only minimize waste but also ensure your products always align with regulatory standards and exceed customer expectations.

Fill level inspection is the heartbeat of consumer satisfaction and safety. Every container must hold the right amount of product. This step preserves the essence of your brand, upholding your reputation by delivering consistently accurate fills.

Our systems offer uniformity, with every batch meeting the mark at perfect fill levels. No more underfilling or overfilling - just the consistent quality your brand promises. With us, your brand's integrity is always preserved.

Our Fill Level Inspection Systems are your key to seamless compliance and quality assurance. Designed to meet industry regulations and standards, they protect your operations against the risks of non-compliance.

Navigating the legal landscape becomes effortless, protecting your business from penalties and other issues. Stay ahead, stay compliant, and let every product reflect integrity.

Our systems deliver impeccably filled products that steer clear of contamination or spoilage. We not only uphold your product's integrity but also deepen customer trust and loyalty.

Level Inspection Systems Work

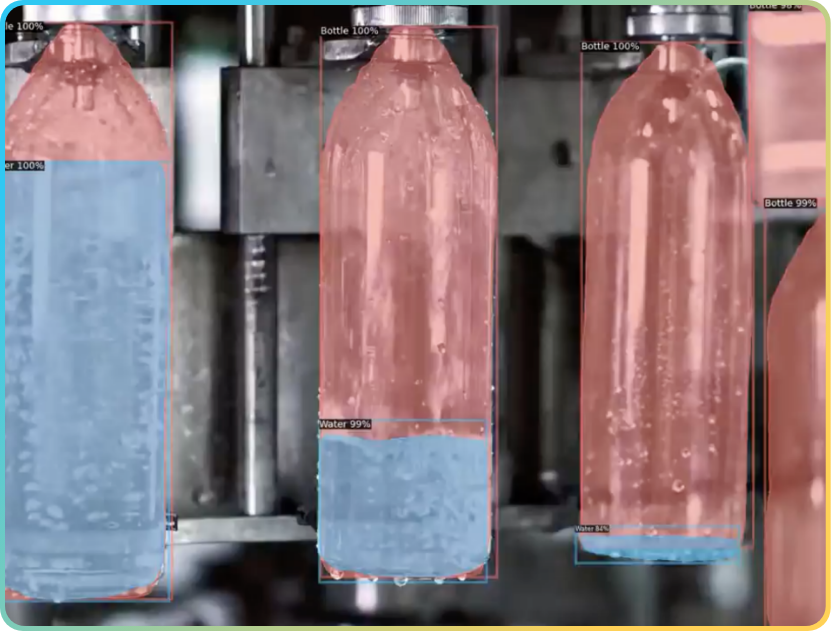

Level Inspection Systems WorkUsing cutting-edge imaging technology, our systems redefine precision in measuring fill levels, identifying variations in the blink of an eye. Designed for flawless integration into your production lines, they boast real-time monitoring, guaranteeing every product shines with your high standards.

Get ready for a world where technology meets customization, all designed to propel your production forward.

At the heart of our Fill Level Inspection Systems lies the fusion of advanced technology and precision. Fitting the needs of your industry and production, our solutions are backed by support and expertise from our vision inspection professionals.

Asked Questions

Asked QuestionsOur systems use state-of-the-art imaging technology to provide highly accurate measurements of fill levels, ensuring consistency across all products.

Yes, our Fill Level Inspection Systems are designed for seamless integration into existing production lines, offering real-time monitoring without disrupting your operations.

By ensuring accurate fill levels, our systems help you comply with industry regulations and standards, avoiding potential penalties and legal issues related to product filling.

Our systems are versatile and can be customized to inspect a wide range of container types and sizes, ensuring flexibility across different product lines.