Inspection System

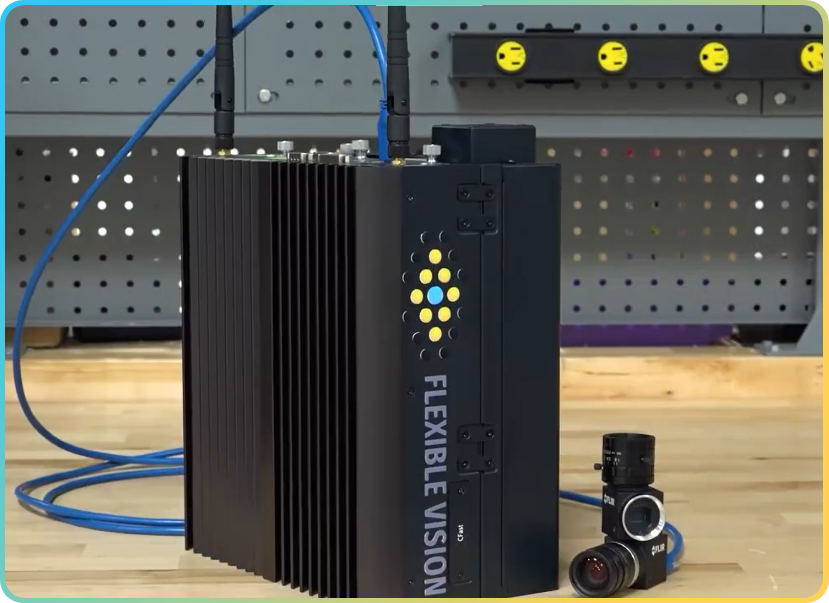

Inspection System Flexible Vision is where precision meets innovation. In the world of production, every detail counts. Our state-of-the-art Floater Inspection System is engineered to perfect cap alignment on small bottles.

Our focus? Elevating product integrity and ensuring your customers are nothing but satisfied. Here, we set new standards for quality by keeping your products safe and reputation sterling.

Floater Inspection Systems?

Floater Inspection Systems?Our Floater Inspection System is your ultimate solution for flawless cap alignment on small bottles. Designed for businesses that refuse to compromise on quality, our system promises precision in cap alignment on small bottles. There's no room for error. It stands guard, identifying any misaligned or improperly seated caps, thus averting the risk of product leakage and guaranteeing that every item exiting your production line is reliable and high-quality.

We zero in on the correct placement and alignment of bottle caps, blocking leaks and spills to prevent waste and contamination. Our system guarantees that every product is perfectly sealed.

Secure seals, trusted quality. Our system protects your product's integrity, preventing quality compromise by ensuring each item is sealed tight and safe from contaminants.

Our Floater Inspection System ensures your packaging meets industry regulations and quality standards, helping avoid penalties and legal issues. Stay compliant, avoid complications.

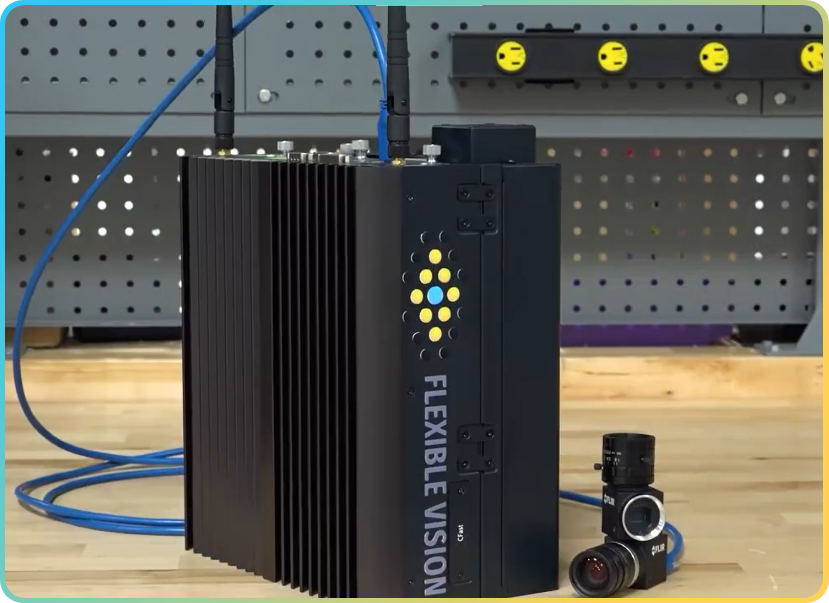

Our advanced imaging technology pinpoints cap misalignments with accuracy, even on dark amber bottles. Seamlessly integrating into your production line, our system delivers real-time quality control.

Our Floater Inspection System swiftly tackles cap alignment issues, minimizing downtime, boosting throughput, and cutting waste. It streamlines your quality control and enhances operational efficiency. With smoother operations, you get better results.

Contact us and take the first step towards flawless production today.

Boost your product's consistency and reliability by correcting cap misalignments effortlessly. Say goodbye to the risks of recalls and customer dissatisfaction.

Asked Questions

Asked QuestionsOur bottle cap inspection system is versatile and capable of inspecting many bottle types, including various shapes and sizes of plastic and glass bottles.

Our system is designed for easy integration with existing production lines. It uses advanced imaging technology that can be seamlessly incorporated into your current setup, requiring minimal adjustments. Our team provides full support throughout the integration process.

Maintenance is straightforward and minimal, ensuring your production line runs smoothly with little downtime. The system is built to last, with a robust design that withstands the demands of continuous operation.