If you are ready to learn more about how Flexible Vision can integrate with your pharmaceutical and medical factory process, reach out to one of our engineers today. We are prepared to help you with all of your unique needs.

Pharmaceutical Manufacturing

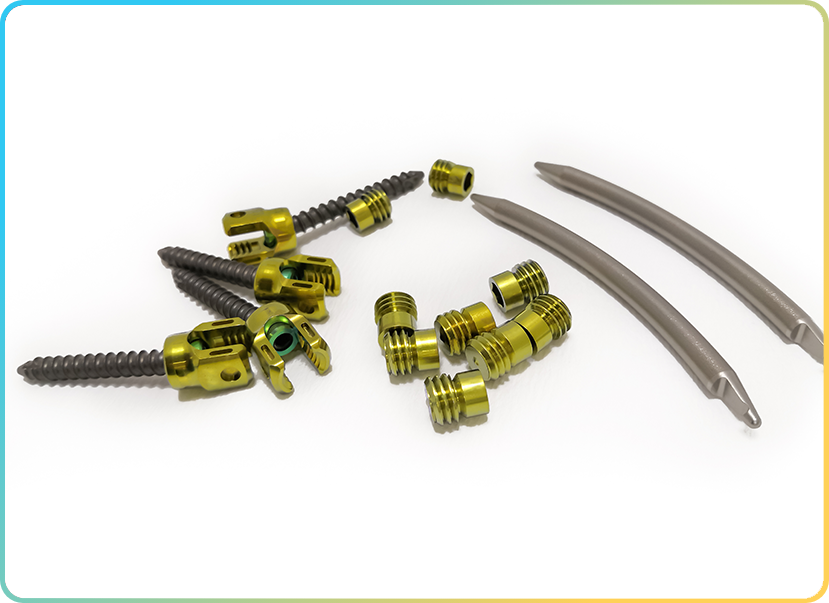

Pharmaceutical ManufacturingFlexible Vision can trace specific quality issues that arise in the manufacturing and QC validation process. In the pharmaceutical and medical industry, our technology helps eliminate any issues that arise while maintaining expert quality control. Functionality includes packaging or pill damage, 2D barcode or pill stamping/labeling validation, bottle desiccant insertion validation, fluid color validation, fill tracking and other key operations.

If a quality issue is detected, our analytics tool will notify the technician and allow them to rapidly trace the issue to a specific node of the manufacturing process.

This ensures that the defect impacts no future products. With real-time updates, technicians are able to stay ahead of problems before they arise.

Flexible Vision’s analytics platform tracks the number of times a quality issue occurs, allowing pharma and medical technicians to quickly identify issues, make adjustments and generate solutions.

Technicians can rapidly deploy new predictions to their models to further tighten quality control processes. In this case, Flexible Vision allows medical-related businesses to seamlessly meet quality and regulatory specifications.

We strive to make technology tangible and accessible for clients of all backgrounds.

This is who we are